| STANDARTS | CLASSIFICATIONS | ||||||||||||||||

| TS EN ISO 14343-A | G 18 8 MN | ||||||||||||||||

| AWS A5.9 | ER 307 | ||||||||||||||||

| SPECIFICATIONS AND APPLICATION FIELDS | |||||||||||||||||

It is used to join high-strength unalloyed and alloyed steels, armor steels, 14% Mn steels, ferritic chromium steels, heat-resistant steels, and aged steels. It is also used for fillet welds resistant to fracture, wear, and cavitation, such as turbines and valves. Argon is used as a shielding gas for TIG welding, and Ar+2.5% O2 or Ar+2.5% CO2 is used for MIG welding. |

|||||||||||||||||

| CHEMICAL PROPERTIES OF WELDING WIRE | |||||||||||||||||

| ANALYSİS TYPE | C | Sİ | MN | CR | Nİ | ||||||||||||

| WELDİNG WİRE | 0,034 | 0,77 | 6,36 | 18,16 | 8,18 | ||||||||||||

| MECHANICAL PROPERTIES OF WELDING WIRE | |||||||||||||||||

TEST TYPE |

SHIELDING GAS (MİG/TİG) |

YIELD STRENGTH (MPA) |

TENSILE STRENGTH (MPA) |

ELONGATION (%) |

NOTCH IMPACT RESISTANCE ISO-V(- 40℃) |

||||||||||||

AFTER WELDING |

M12-M13-M14-I1 | MİN 400 | MİN 580 | MİN 30 | MİN 63 J | ||||||||||||

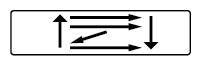

| WELDING POSITIONS | |||||||||||||||||

|

|||||||||||||||||

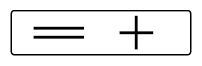

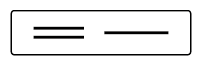

| SHIELDING GAS (MİG/TİG) |

POLARIZATION (MİG/TİG) |

||||||||||||||||

| M12-M13-M14 / I1 |  |

|

|||||||||||||||

| PACKAGING INFORMATION | |||||||||||||||||

| DIAMETER (MM) |

PACKAGING TYPE |

NET WEIGHT OF 1 PIECE (KG ) |

|||||||||||||||

| 1,00 | METAL SPOOL | 15 | |||||||||||||||

| 1,20 | METAL SPOOL | 15 | |||||||||||||||

| 1,60 | PLASTİC BOX | 5 | |||||||||||||||

İnternet sitemizden en iyi şekilde faydalanabilmeniz ve internet sitemize yapacağınız ziyaretleri kişiselleştirebilmek için çerezlerden faydalanıyoruz. Dilediğiniz halde çerez ayarlarınızı değiştirebilirsiniz. Detaylı bilgi için tıklayınız