| STANDARTS | CLASSIFICATIONS | |||||||||||||||||

| TS EN ISO 14343-A | G 19 12 3 LSİ | |||||||||||||||||

| AWS A5.9 | ER 316LSİ | |||||||||||||||||

| SPECIFICATIONS AND APPLICATION FIELDS | ||||||||||||||||||

It has excellent resistance to welding austenitic stainless alloys, particularly in acidic and chlorinated environments. The alloy's low carbon content makes it particularly suitable for areas with a risk of intergranular fracture. A higher silicon content improves weld properties such as wetting. The alloy is widely used in the chemical and food processing industries, as well as in various economical and architectural applications. |

||||||||||||||||||

| CHEMICAL PROPERTIES OF WELDING WIRE | ||||||||||||||||||

| ANALYSIS TYPE | C | Sİ | MN | CR | Nİ | |||||||||||||

| WELDIN WIRE | 0,020 | 0,85 | 1,73 | 18,40 | 11,20 | |||||||||||||

| MECHANICAL PROPERTIES OF WELDING WIRE | ||||||||||||||||||

TEST TYPE |

SHİELDİNG GAS |

YIELD STRENGTH (MPA) |

TENSILE STRENGTH (MPA) |

ELONGATION (%) |

NOTCH IMPACT RESISTANCE ISO-V(- 40℃) |

|||||||||||||

| KAYNAK SONRASI AFTER WELDING |

I1 | MİN 410 | MİN 560 | MİN 35 | MİN 63 | |||||||||||||

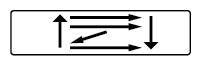

| WELDING POSITIONS | ||||||||||||||||||

|

||||||||||||||||||

| SHIELDING GAS | POLARIZATION | |||||||||||||||||

| M12-M13-M14 |  |

|||||||||||||||||

| PACKAGING INFORMATION | ||||||||||||||||||

| DIAMETER (MM) |

PACKAGING TYPE |

NET WEIGHT OF 1 PIECE (KG ) |

||||||||||||||||

| 0,80 | METAL SPOOL | 15 | ||||||||||||||||

| 1,00 | METAL SPOOL | 15 | ||||||||||||||||

| 1,20 | METAL SPOOL | 15 | ||||||||||||||||

İnternet sitemizden en iyi şekilde faydalanabilmeniz ve internet sitemize yapacağınız ziyaretleri kişiselleştirebilmek için çerezlerden faydalanıyoruz. Dilediğiniz halde çerez ayarlarınızı değiştirebilirsiniz. Detaylı bilgi için tıklayınız